All-in-One Tool Gets Mold and Die Makers to Finish Line Faster

Hexagon Manufacturing has bundled its state-of-the-art technologies into a suite of tools, giving mold and die shops of all sizes a competitive edge.

January 24, 2024

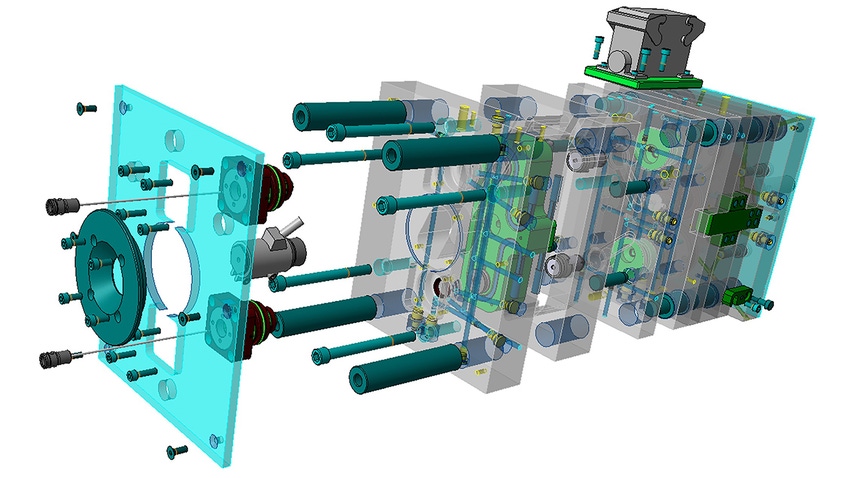

Mold and die manufacturers just got a powerful new all-in-one tool from Hexagon Manufacturing that bundles the company’s technologies into a suite of tools allowing plastic flow analysis, reverse engineering, modeling of solids and surfaces, and more.

The HxGN Mould and Die suite from Hexagon’s Intelligence Division expands upon the company’s VISI and WORKNC software.

"We took everything we know about mold-and-die manufacturing, including our best-in-class Hexagon technologies, to build a specialized suite that empowers mold and die shops of any size to get the best results faster," said Chuck Mathews, general manager of production software at Hexagon. "Their competitive edge will be enhanced with Nexus, which connects desktop software via the cloud to provide further automation and collaboration opportunities. It also gives teams an easy way to share 3D models with customers through secure web-based visualization, and consolidates access to libraries for tooling, fixtures, and materials from their desktop apps."

For injection mold makers, the HxGN Mould and Die suite integrates CAD/CAE/CAM workflow to provide data-based insights into mold creation and function through:

Simulation tools to help determine the feasibility and cost of mold making;

plastics flow analysis tools to produce cost-effective and reliable molds;

automated design and simulation of electrical discharge machining electrodes and holders to simplify the creation of intricate or hard-to-machine mold features;

multi-axis CAM programming capabilities;

reverse-engineering tools to efficiently create solid models from scanned data, particularly useful for repairing or redesigning molds;

an extensive material characteristics database;

automated core and cavity extraction;

smart cooling channel definition;

thermal prediction and simulation;

warpage estimation and compensation.

"The HxGN Mould and Die suite is an exciting development, combining our customers’ challenges with our deep domain knowledge to achieve more," said Parth Joshi, chief product and technology officer at Hexagon. "We are refocusing innovation to bring our ecosystem technologies together and help production teams make better-informed decisions, faster."

About the Author(s)

You May Also Like