New Injection Molding Nozzles Improve Gate Quality, Facilitate Maintenance

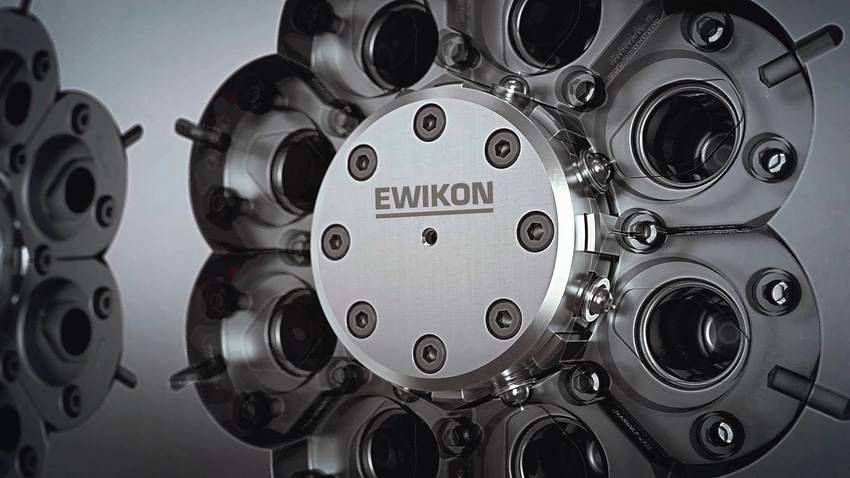

Hot-runner supplier Ewikon will feature an expanded selection of nozzles for side gating at NPE.

April 16, 2024

Hot-runner system supplier Ewikon will show off an expanded range of nozzles for direct side gating for injection molding during NPE2024 in Orlando, FL, from May 6 to 10.

Ewikon’s pro Edge VG range is growing with a valve gate version the company says improves gate quality and flexibility while being easier to maintain.

Integrated wear parts.

In this new nozzle, all wear parts — valve pin, valve pin guide, and valve pin seal — are integrated into one assembly for each gate.

And, this nozzle can be configured with up to eight tip inserts, each with unique flow channel layout, for equal flow paths and uniform filling of all cavities. Mold stability is improved because mold inserts do not have to be split to install the nozzle.

For tough applications, molders can change the position of the injection point. Gating can also be performed on various geometries in which side gating wasn’t possible because of insufficient shear surfaces; all that is required is an area about the gate diameter of the valve pin.

Precise actuation.

Valve pins are actuated precisely thanks to a linear servomotor with advanced control technology. Stroke and opening speed can be varied continuously depending on process requirements.

For ease of maintenance and to reduce down time, the gate assembly can be changed directly on the machine from the parting line without having to dismantle the mold.

Visit Ewikon at booth W1581 at NPE2024 in the Orange County Convention Center in Orlando, FL, from May 6 to 10.

About the Author(s)

You May Also Like