Plastic Loses Amazon Pillow Fight

Ecommerce giant aims to convert 100% of the plastic air pillows to paper filler packaging in North America by end of year.

At a Glance

- Amazon has already replaced 95% of its plastic air pillows with paper filler.

- Move eliminates nearly 15 billion plastic pillows annually.

- Paper filler is made from 100% recycled content that’s curbside recyclable.

Say goodnight to plastic air pillows from Amazon. The company has already replaced 95% of the plastic pillows from delivery packaging in North America with paper filler and is working toward full removal by the end of the year.

It’s the next big step away from plastic since last October when it replaced plastic shipping materials at a facility in Ohio. That conversion included heat-sealable paper, paper fill, and lightweight corrugated board.

“We’re constantly inventing and thinking big to make our packaging small,” Amazon staff write in a blog post June 20. “We want to ensure that customers receive their items undamaged, while using as little packaging as possible to avoid waste and prioritizing recyclable materials.”

This move away from plastic is even bigger. “To date, this will be Amazon’s largest plastic packaging reduction effort in North America and will avoid nearly 15 billion plastic air pillows annually. For Prime Day this year, nearly all customer deliveries will not contain plastic air pillows.”

The move is part of a broader commitment to reduce packaging.

“I’m proud of the cross-Amazon collaboration to make a positive impact on the customer delivery experience with easier to recycle materials,” says Pat Lindner, VP of mechatronics and sustainable packaging. “It’s a great example of how we thoughtfully test and scale new solutions to protect our customer experience. We are working towards full removal in North America by end of year and will continue to innovate, test, and scale to prioritize curbside recyclable materials.”

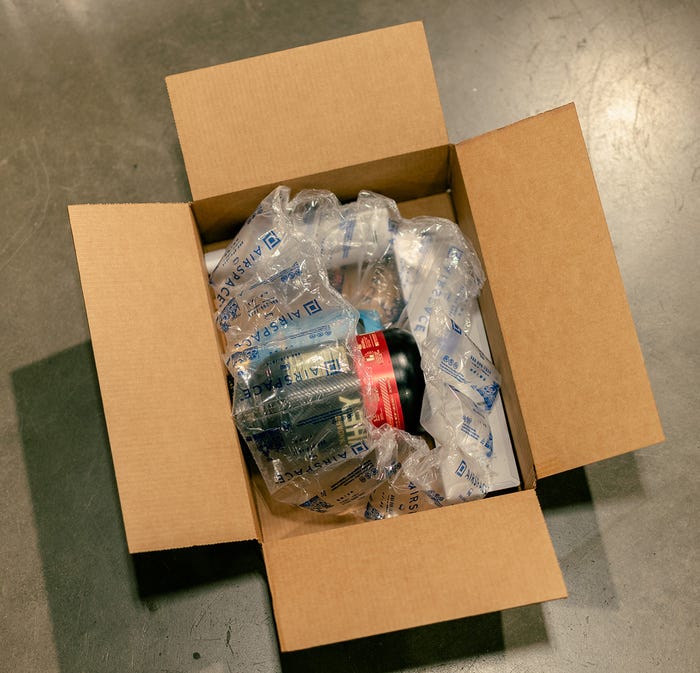

Amazon's boxed shipments will now feature paper void fill rather than plastic pillows. AMAZON

Broad-scale rollout involved hundreds of sites.

To achieve that breakthrough, Amazon’s teams collaborated with suppliers to source paper filler made from 100% recycled content. The teams also coordinated the transition across hundreds of fulfillment centers. This included working with thousands of employees to change machinery as well as to host employee trainings for these new systems and machines.

By testing paper filler —which included an assessment by a third-party engineering lab — Amazon discovered it offered the same, if not better, protection to products than plastic air pillows.

A key sustainability aspect is that the paper, made from 100% percent recycled content, is also curbside recyclable.

Soon, consumers will no longer find plastic pillows in their Amazon shipments in NA. AMAZON

It was embraced by Amazon’s fulfillment center teammates.

“I’m so excited we’re changing over to paper,” says Christian Garcia, fulfillment associate at a fulfillment center in Bakersfield, CA. “It’s not only easier to work with, but the machinery gives us more space so it’s easier to pack orders. I’m proud to be a part of a change that allows customers to recycle at home.”

In 2022, 11% of all packages shipped by Amazon globally were without added Amazon delivery packaging through its Ships in Product Packaging certification program.

Amazon is also working to invent new materials and recycling solutions that keep both customers and the environment in mind. For example, Amazon teamed with the U.S. Department of Energy to develop new materials and recycling programs.

The blog shares that it’s “also piloting new technology with Glacier, a San Francisco-based artificial intelligence (AI) and robotics company, to use AI-powered robots to automate the sorting of recyclables and collect real-time data on recycling streams for companies—which can help reduce landfill waste and increase the use of recycled materials in packaging.”

All told, it’s one big pillow fight that ends in plastic’s disfavor.

About the Author(s)

You May Also Like